Product Range

Parker Electro Mechanical

Parker Linear Belt Actuator

We offer our clients a comprehensive variety of Parker OSPE.B Belt Driven Linear Actuator which offers a cost effective solutions aimed at small to medium industrial applications that calls for high speeds and long travels. The OSPE.B comes in a standard range with a core slider bearing guide. It belongs to the Origa System Plus family, reputed for efficient delivery of premium quality and cost effective ownership.

Specifications:

- 3 bore sizes available: 25, 32 and 50

- Max normal load = 850 N (190 lbs)

- Standard travel up to 5 meters

- ±0.05 mm/m bidirectional repeatability

- Internal slider bearing guide standard

- Externally attached bearing options for higher loads and moments

- IP54 strip seal

- 8000 km life rating

Belt Driven Linear Actuators ~ Standard

| Max. Load | Max. Thrust | Max. Travel | Max. Velocity | Repeatability (+/-) | |

| ER Series - Electric Rodless Actuators | 222 kg | 3600 N | 1.5 m | 5 m/s | 0.025 mm |

| ERV Series - Electric Rodless Value Series | 359 kg | 808 N | 6 m | 5 m/s | 0.2 mm |

| HLE-RB | 600 kg | 2235 N | 7.9 m | 5 m/s | 0.2 mm |

| HPLA | 1375 kg | 6000 N | 9.0 m | 5 m/s | 0.2 mm |

| HLE-SR | 600 kg | 1650 N | 6.0 m | 3 m/s | 0.2 mm |

| HLE-RB Spliced | 600 kg | 2800 N | 30 m | 5 m/s | 0.2 mm |

| HLE-Z Rack & Pinion Drive | 600 kg | 1750 N | 50 m | 5 m/s | 0.05 mm |

| LCB Series | 30 kg | 160 N | 5.5 m | 8 m/s | 0.3 mm |

| HTR/HZR Vertical Actuators | 150 kg | 2200 N | 4 m | 5 m/s | 0.5 mm |

| OSPE B Belt Actuator | 85 kg | 425 N | 5.0 m | 5 m/s | 0.05 mm |

| OSPE BHD Belt Actuator with Integrated Ball Bearing | 1500 kg | 3120 N | 6.0 m | 10 m/s | 0.05 mm |

We also offer Parker Linear Belt Actuator in other series such as HPLA , HLE-RB, ERV Series Besides the regular OSPE.B

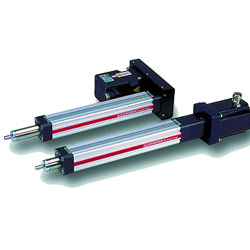

Parker Electric Cylinder

Clients can now enjoy the efficient services offered by Parker Electric Cylinders. The Parker ET Series Electric Cylinders is an amalgamation of brilliant design with wide ranging feature selections allowing it be out to use for both new and existing applications.These products offered by us are manufactured as per hard metric ISO standards, the ET Series can be placed into current fluid power cylinder applications. This result in unlimited programmability to the durability and long life expected of hydraulic and pneumatic cylinders. Facilitated with Parker Hannifin motor and control system, the ET Series is one of the best electric cylinders to serve the critical specifications of clients.

ET Series Design Features:

- Precision anti-rotation roller bearing rod support carriage

- Angular contact thrust bearings

- Anodized aluminum cylinder body

- Five profile sizes (32, 50, 80, 100, 125 mm)

- Precision rolled ball screws or Acme lead screws

- Inline or parallel motor mounting

- Six different rod end options including Linear Rod Guide Module for additional side load support

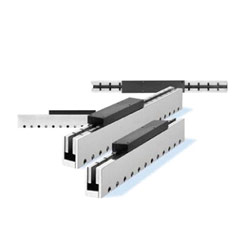

Parker Multi-Axis System

Multi-Axis Connection System - simplifies engineering and installation We are introducing our clients to the perfection of Parker Multi-Axis Connection System which is a versatile system for connection of linear drives in multi-axis arrangements. With highly adaptable range of adapter plates, profile mountings and intermediate drive shafts simplify engineering and installation.

The connection system allows actuators to be attached in the following configurations:

- Carrier to carrier

- Carrier to profile

- Carrier to end cap mounting

Suitable for the heavy duty belt drive series OSP-E BHD, the system offers cross-connection with the same series and also other linear drive series in the ORIGA SYSTEM PLUS range.

Multi-Axis Systems Applications:

- Delivers integrated customized solutions for motion control requirements.

- From one location, Parker manufactures 3 core technologies: gearheads and gear motors, linear positioning systems, and servo motors and amps.

- This provides our engineers with the ideal ability to integrate precision products and components into one complete, turnkey motion control system. before it leaves the facility.

- The range combine linear and rotary motion, servo motors and amps, precision gearing, and motion controllers into high performance, automated "drop-in" solutions that fit seamlessly within client application, saving time, trouble and effort.

- Parker systems pack a tremendous amount of performance into "small footprint" designs, making it possible for companies to improve yield and increase throughput with smaller equipment and facilities.

Parker Linear Motors

We facilitate our clients with the superb engineering skill of Parker Hannifin who have been delivering groundbreaking automation solutions for decades. The same efficiency is to be found within the exploding market of linear motor technology. Parker Linear Motor solutions are reputed for brilliant automation and robotics. It results in customer's distinct performance enhancements and cost of ownership benefits over competing technologies. A linear motor functions in precisely the same method as a rotary motor that has been "unwrapped." The same electromagnetic effects that produce torque in a rotary motor now produce a direct force in a linear motor. For many applications, linear motors offer distinct advantages over conventional rotary drive systems. For example, there is no need to couple the motor to the load by means of intermediate mechanical components such as gears, ball screws, or belt drives.

Typical applications for Parker linear motor products include:

- Semiconductor and electronics

- Flat panels, solar panels

- Medical and life sciences

- Machine tools

- Optics and photonics

- Large format printing, scanning and digital fabrication

- Linear Motor Design

Benefits of the system:

- High speeds

- High accelerations

- Fast response—100 times that of a mechanical system

- Stiffness-spring rate better than a mechanical system

- Zero backlash-direct drive technology

- Maintenance free operation–mechanical simplicity due to reduced component count

- Long travels without performance loss

- Suitable for vacuum and extreme environments

Parker Linear Ball Screw Actuator

The Parker Linear actuator with ball screw that we bring for our clients is a perfect combination of adaptability and rugged construction in a solid motion stand that is ideal for continuous process automation. A brilliant ball screw drive, recirculating square rail bearings and high strength aluminum body diminishes costs while scaling performance. The 400XR Precision Linear Tables is reputed for accurate arrangement, consistent performance, rugged features and adaptability. Fine performance, modular compatibility, and fast delivery have made these tables the perfect building blocks for cost-effective multi-axis systems. Modular flexibility sets this range apart distinguishes from all others permitting easy configuration to meet unique requirements from the very basic to the highly complex.

Specifications:

- Travels to 700 mm

- 100% Duty Cycle

- Repeatability to ±20 µm

- High Strength Design

- Multi-Axis Mounting

- Locating Dowel Holes

- Linear feedback

- Sensor packs

- Parallel motor mounting

- Clean room preparation

Advantages:

- Accurate path and position control

- High force output

- Easy installation

- Excellent slow speed characteristics

- Ideal for precise traverse operations

- (e.g. machine feeds) and lifting applications

Features:

- Integrated drive and guidance system

- Complete motor and control packages

- Diverse range of accessories and mountings

- Optimal screw pitches (5, 10, 25 mm)

Parker Precision System

We offer Parker Precision System to meet the need for greater heat dissipation in high ambient environments. Parker offers Two-Phase Evaporative Liquid Cooling is "mission-critical". The range has standard containers for grid energy storage for wind and solar farms, constructed as per customer requirements for infield battery and power conversion. Perfect for industrial , renewable energy and even data center applications, Parker's patented 2-phase "evaporative" precision cooling systems can upsurge the power output for high power systems by up to 40%. Further, the competent cooling system can escalate electronics density by 2X or more, or simply reduce existing packaging size.

Application:

- Renewable Energy

- Grid Energy Storage

- Data Centers

- HE Industrial Vehicles

- Military Ground Vehicle applications.

Features:

- Parker's two-phase evaporative cooling system uses a refrigerant that is non-corrosive and nonconductive to cool electronics in a closed-loop, highly efficient system that is fully modular, as well as lighter, safer and more reliable than traditional thermal systems.

- The system uses a small pump to deliver just enough coolant to the evaporator -usually a series of one or more cold plates optimized to acquire the heat from the device being cooled.

- The two-phase coolant vaporizes to maintain a cool uniform temperature on the surface of the device.

- The vaporized coolant is pumped to a heat exchanger, where it rejects heat to the ambient, and condenses back into a liquid, completing the cycle.

Benefits :

- Smaller, lighter, safer and more reliable than traditional cooling systems

- 2-4 times better heat transfer

- Evaporative cooling system is Isothermal - The system dynamically optimizes to heat load

- 40% increase in electronics throughput

- Enables up to 2X the power density in the same space

- Uses 80% less liquid, which means less weight. and less space

- 85% reduced energy consumption for cooling

- Modular & Scalable

- No altitude or hot climate de-rating necessary

Parker Servo Drive

Our range of Parker SSD Drives servo products that we directly source from Parker covers extensive variety of power ranges and applications, Parker servo products include application development and configuration software, as well as industry standard bus communication protocols. Suitable for the most challenging servo systems, the ultra-fast control loops and process bus make the Parker servo drive perfect for single or multi axis applications.

Indexing tables are generally mounted on:

- Printing machinery (shiftless)) high performance test equipment, multi-axis, torque motor control, very high power applications.

- Machine tools, where optimum speed or torque regulation is required. (Integrated resistor or regenerative braking)

- Packaging machine, palletization and most special purpose machinery. (Internal motion controller)

- RTS servo amplifier is designed for driving DC servo motors. They integrate main supply, auxiliary supply and braking resistor circuits in a compact packaging

Feature & Application:

| Range | Control | Safety | Applications | |

| Modular systems drive | ||||

| AC890 series | Up to 1171 A | Open or closed loop PMAC servomotors control | Standard, EN18849-1, Ple or SIL3 | Printing machinery (shaftless) High performance test equipment,, Torque motors control. |

| Regional servo drives | ||||

| Digivex series | 2 to 300 A | Speed control (Digivex Drive) or motion control (Digivex Motion) | No | Machine tools, optimum speed or torque regulation, (Integrated resistor or regenerative braking) |

| 630 series | 2 to 30 A | Torque, speed or position | Category = 3, EN18849-1 | Packaging machine, palletization and most special purpose machinery. (Internal motion controller) |

| RTS series | Up to 40 A | U-RI or tachometer control | No | RTS servo amplifier are designed for driving DC servo motorsThey integrate main supply, auxiliary supply and braking resistor circuits in a compact package |

Parker Servo Stepper Motor

We source from Parkers the world renowned variety of Parker Servo Stepper Motor that is available in electric, hydraulic and pneumatic technologies in varied range of sizes and configuration including rotary and linear. The Parker Servo Stepper Motor finds application in unimaginable variety of requirements ranging from miniature brushless motors to high power hydraulic motors used in earth moving equipment. Parker motor systems are designed to meet almost any motion control need, and help one to select standard products or provide rapid design integration solutions.

Parker Motors include:

- Permanent magnet AC brushless servo

- DC brushed servo

- Kit motors for OEM applications

- Torque / Direct drive

- Linear Servo

- Low Speed, High Torque hydraulic

- High Speed Hydraulic

- Spur Gear Hydraulic

- Vane Hydraulic

- Radial Piston and Vane Air

Parker Motorised Positioning System

The comprehensive range of Parker Motorized Positioning System offered by us carries the competence of the world renowned Parkers. This perfect fit" electromechanical device offers solutions for top of the range positioning and high-speed automation. Parker-Daedal presents a comprehensive range of linear and rotary, manual and motorized positioning tables. These offer hundreds of standard products but also have the engineering resources to custom design and build unique positioning systems. Positioning technology comprises belt drives, ball bearings, precision ground and rolled thread ball screws, cross roller bearings, precision ground lead screws, rotary bearings, precision ground and lapped worm gears.

Planetary Gear Head

We offer a very efficient range of Planetary Gearhead that is enriched with high torque capacity per unit weight and volume as well as low backlash and high stiffness. We source the range from world's most renowned manufacturer of the product. We bring planetary gearheads in a variety of sizes in inch-series diameter codes from Size 8 to Size 80 (.8" to 8") corresponding with our standard servo motors. We equip these units as complete vehicle level line-replaceable units (LRUs), including hinge lines, as required by the overall system design philosophy.

Features:

- Our planetary gearhead features high torque capacity per unit weight and volume, as well as low backlash and high stiffness.

- The output bearing pair span in our planetary gearhead architecture provides maximum radial stiffness against the mating forces of the payload.

- We can optionally supply the output pinion of the planetary gearhead split and torsional spring loaded against it, to eliminate backlash to the payload’s mating gear

Application:

- Aerospace

- Defense motion -control applications.